Production method of wax

|

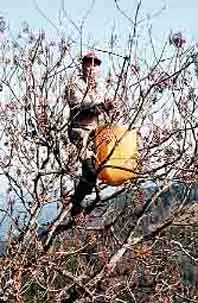

Act.1 Gathering the nuts of Rhus succedanea, the material for wood wax Rhus succedanea or the "Haze tree" belongs to Anacardiaceae, and the nut of the plant is gathered. Cultivation of this tree is not so old, probably started since early Edo era. The tree is widely cultivated in warm areas like Kyushu, Shikoku, and Okinawa. The new leaves of the tree cause rashes for many people if they touch them. However, it is not harmful after the leaves fall in the middle of November. The nut of the tree changes the color from green to cloudy yellow when it is suitable for gathering. |

| ↓ | |

|

Act.2 Inside of the nuts warehouse |

| ↓ | |

|

Act.3 Pulverize the nuts Using millstone, the nuts are pulverized. |

| ↓ | |

|

Act.4 The pulverized nuts This makes about 60 kg(132 Lb) wax. |

| ↓ | |

|

Act.5 And steam them. |

| ↓ | |

|

Act.6 The steamed pulverized nut is squeezed by pressure. |

| ↓ | |

|

Act.7 Oil pressure is used for squeezing |

| ↓ | |

|

Act.8 Squeezed out wastes |

| ↓ | |

|

Act.9 When it is liquid, it is put in the mold for hardening. |

| ↓ | |

|

Act.10 Upper photo is the hardened pulverized nuts after squeezing. Lower photos are nuts of the tree (lower right), nuts(center), and the waste(lower left). |

| ↓ | |

|

Act.11 Our workshop uses this kind of good quality wood wax. |

| Trivia about Japanese wax "Haze tree" Rhus succedanea or "Haze tree" is deciduous belongs to Anacardiaceae. In the end of 16th century, a Japanese named Sojin Kamiya (1551~1635) imported the tree from the southern part of China and planted in Karatsu area in Northern Kyushu. Later, it expanded to Chikuzen area (now Fukuoka prefecture). Since the beginning of Edo era, production and demand of tree wax had increased. As the wood wax has a sticky minute organization, it won’t make cracks or specks when candle is made. It is said the reason candles made of wood wax are fat on the upper part is to obtain a large flame and light for awhile after ignition. "Usage of wood wax" Wood wax is mainly used for candle, but exposed wax is used for ointment, polishing substance and cosmetics such as pomade. "Exposed wax (called "white wax" also)" To make it, a liquid state of heated wood wax is gradually dripped to a clear water to make solid wax as thin as possible. Then, it is exposed under sunlight for 30 to 40 days. How to make "Candle"? Production method of wick is here. Click Our Candle. |

|